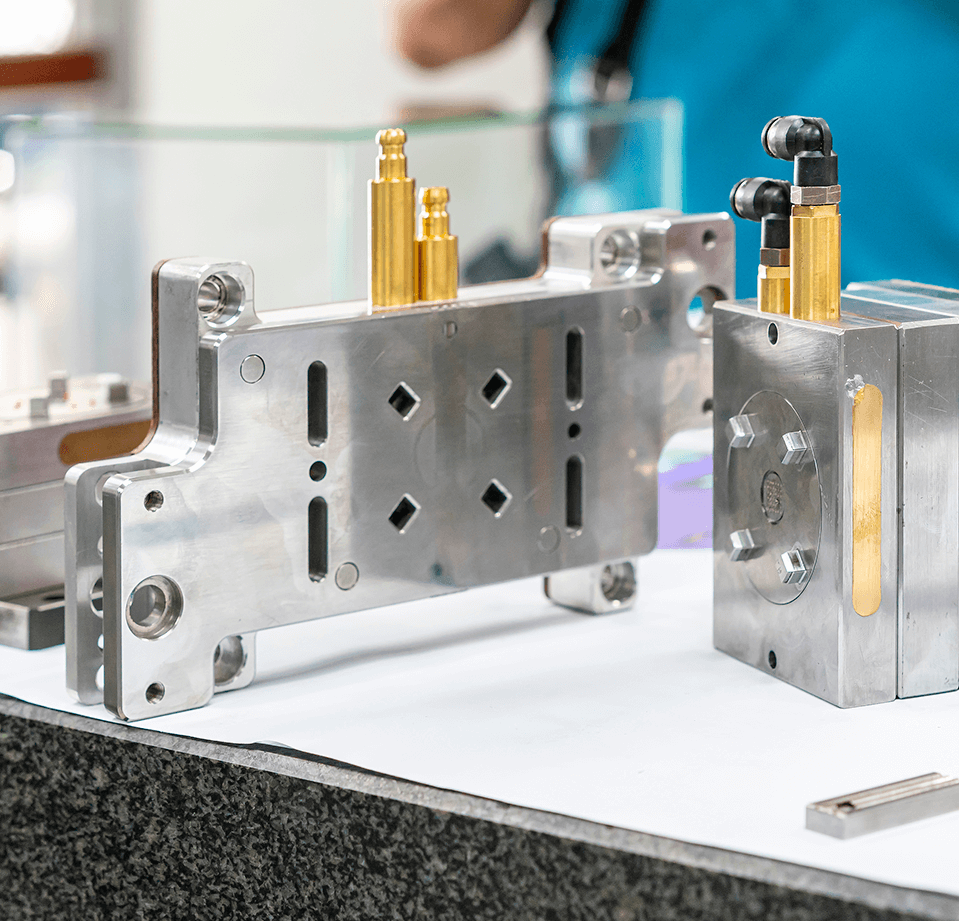

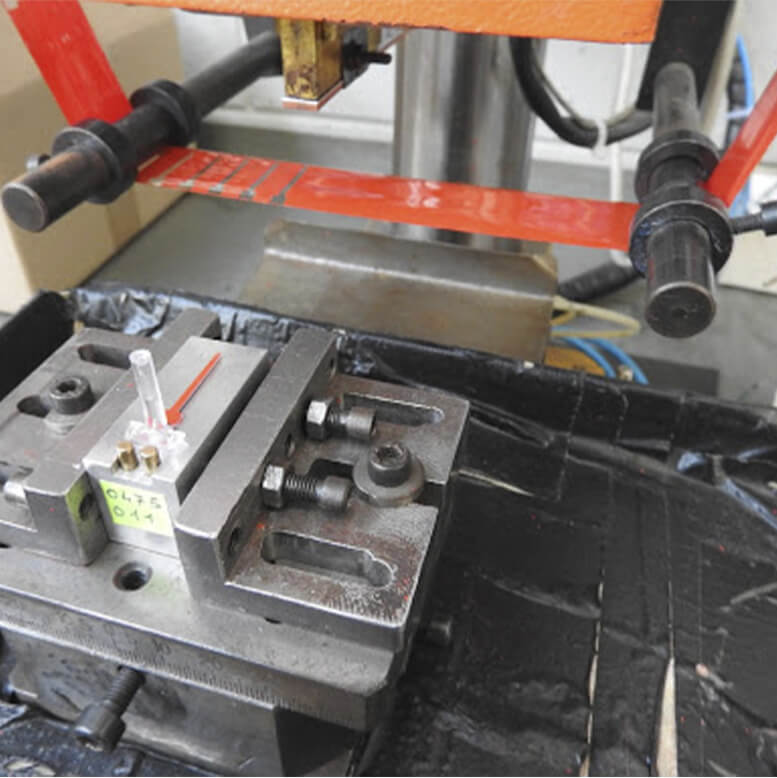

Molds:

design and production

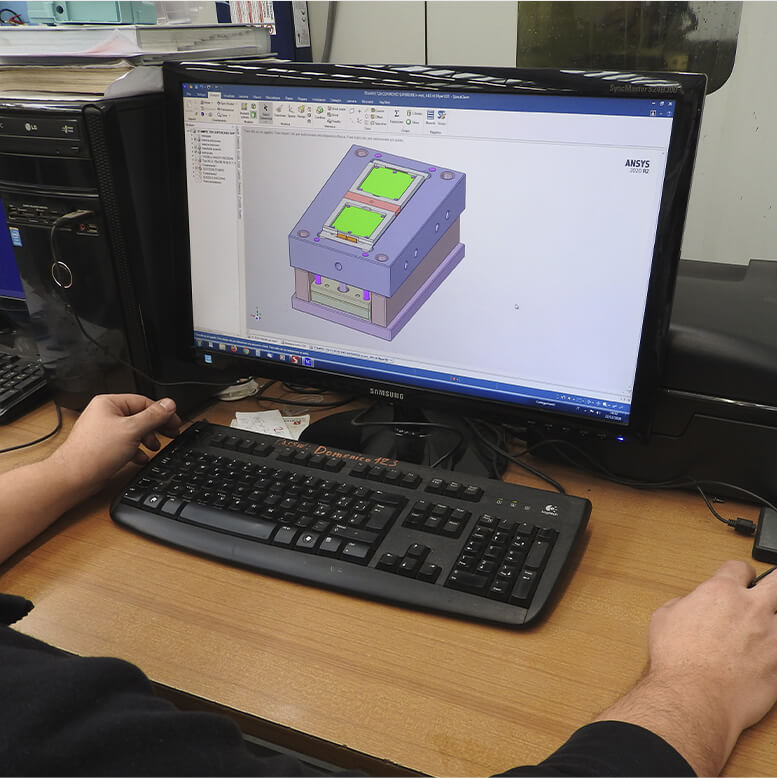

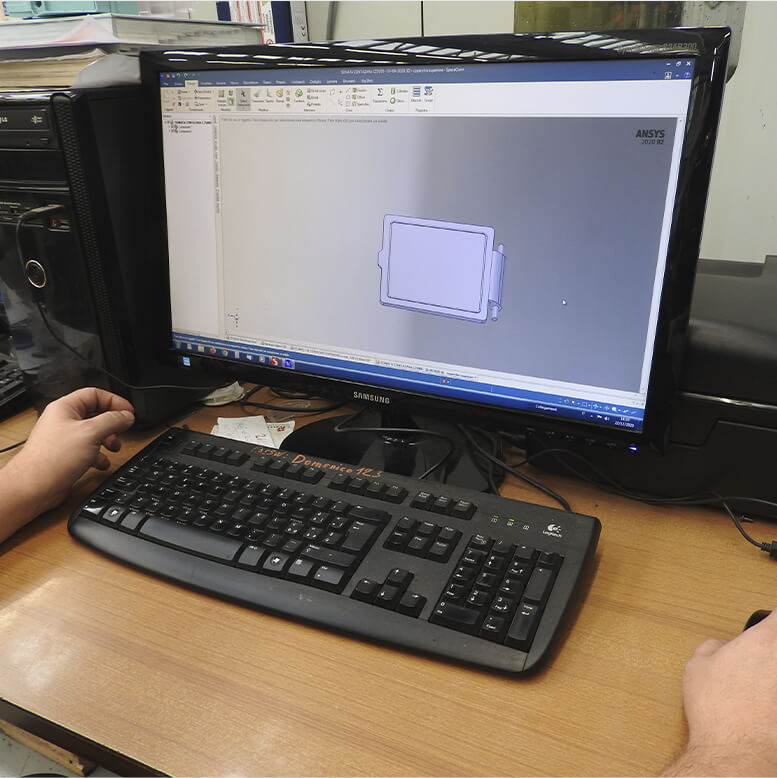

Starting from the 3D drawing of the article to be produced, we proceed to the design and engineering of the mold, optimizing costs and quality of the product.

Thanks to the wide range of machinery and equipment, we are able to carry out any processing necessary for the realization of the mould.

This allows us to intervene quickly both in case of repair and modification of the moulds.

Injection moulding,

Two-component moulding,

Manual moulding

We are equipped with 25 hydraulic, hybrid and electric presses with clamping force from 25 to 120 TON, all equipped with robot gripper. 4 presses in particular are bi-component, dedicated to moulding the entire range of our rollers.

Over the years we have invested in the automation of our production plants and today we are able to guarantee a 24 hour production for large volumes.

The experience gained over the decades and the presence in the department of specialized technicians, allows us to have considerable flexibility on mold changes for emergencies and / or special needs of the customer.

Technical assembly

We have a specific department dedicated to the assembly of technical articles.

Moreover, for large volume orders we can count on the support of qualified external suppliers, whose equipment is certified by our technical department.

This department is also in charge of the control of the products that have been assembled from external suppliers: a control card prepared by our technical department indicates all the specifications that the assembled product must comply with in order to be accepted.

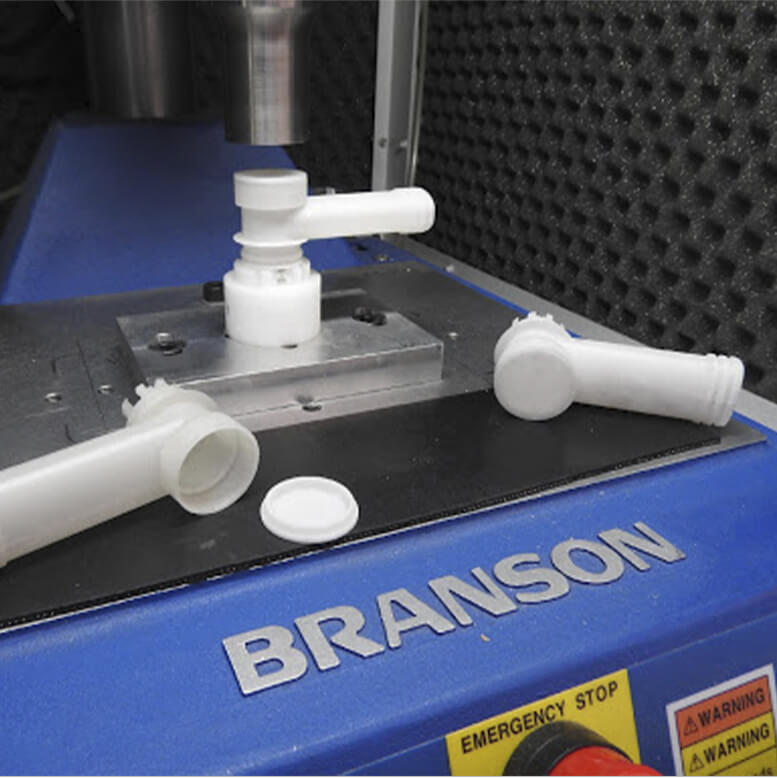

Ultrasonic

Welding

To meet the growing demand for this type of work, we are equipped with 3 Branson ultrasonic welders with up to 3,300 watts of power.

Hot screen printing

To meet the growing demand for this type of work, we are equipped with 3 Branson ultrasonic welders with up to 3,300 watts of power.

Quality control

We have a quality control department for our thermoplastic production.

Technicians check several times a day that the production of each press complies with the specifications indicated in the control sheets that our technical department prepares for each item.

All the components we receive from our suppliers must also go through the acceptance process of our Quality Department.